News

-

Residues in the mould cavity are one of the reasons that cause under-casting

During the production process of die-casting parts, there will be many quality problems, that is, as a common quality defect of die-casting parts, one of which is under-casting, which causes the under-casting of die-casting parts. as follows: During the forming process of die-casting parts, some p... Read more

23-05-2023 Industry News -

Assemble the concave mould should be placed horizontally

In the process of using the continuous stamping die, it is very necessary to do maintenance work, and it is necessary to carry out maintenance work carefully and patiently, so as to ensure the safety and usability of the continuous stamping die. Maintenance of punch and die When disassembling th... Read more

23-05-2023 Industry News -

The difference between die extrusion and injection moulding

Extrusion It is a moulding method to make plastics in viscous flow state through high-temperature and certain pressure, through a die with a specific cross-sectional shape, and then at a lower temperature to form a continuous profile of the desired cross-sectional shape. The production process of ... Read more

23-05-2023 Industry News -

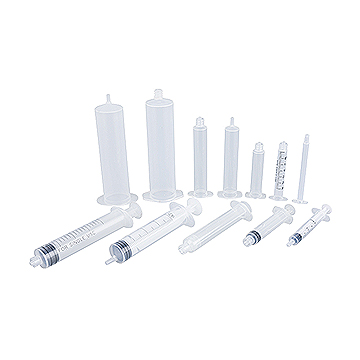

Overhaul skills of syringe mould parts

Mould accessories are very important for the use of injection syringe moulds, so we need to regularly inspect the mould accessories during use, which not only helps the use of moulds greatly, but also can pick the service life of jnjection syringe mould accessories.The following are related mould ac... Read more

23-05-2023 Industry News -

Common defects of disposable medical device injection moulding

We all know that some defects often occur in Disposable medical device mould after moulding. This time seriously affects the normal use of workpieces, and even makes the manufactured workpieces unusable. This will seriously affect the cost and efficiency of manufacturing workpieces. Therefore, we mu... Read more

23-05-2023 Industry News -

Seven suggestions for reducing defects during mould processing

As an important tool for the manufacture of workpieces, Disposable medical device moulds will inevitably have some defects during the processing process, which will cause the workpieces to be unable to be used normally or even to be used after manufacturing. 1. Reasonably select and trim the grind... Read more

23-05-2023 Industry News -

Reasons for surface oxidation after mould nitriding

Die nitriding is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the medical treatment mould. If surface oxidation occurs after nitriding the mould, it not only affects the appearance quality of the mould, but also affects the hardness and wear resistance of the mo... Read more

23-05-2023 Industry News -

How to improve the quality of medical device mould

With the improvement of technical requirements, the demand for medical device mould quality is constantly increasing. Therefore, when we re-manufacture moulds, we need to improve the quality of the moulds as much as possible. The following are the five ways that China Standard Parts Network can shar... Read more

23-05-2023 Industry News -

Causes and preventive measures of damage to the syringe needle base mold

In die casting production, the most common form of mold damage is cracking and cracking. Stress is the main cause of mold damage. Thermal, mechanical, chemical, and operational shocks are all sources of stress, including mechanical stress and thermal stress. Stress is generated by: (1) The quality p... Read more

23-05-2023 Industry News -

Several factors to be considered in designing nozzle mold

1. Plastic mold processing parting surface, that is, the contact surface where the concave mold and the convex mold cooperate with each other when the mold is closed. The selection of the location and form of plastic mold processing is affected by factors such as product shape and appearance, wall t... Read more

23-05-2023 Industry News -

Nozzle mold shrinkage and its influencing factors

The characteristic of thermoplastics is that they expand after heating and shrink after cooling. Of course, the volume will shrink after pressurization. In the injection molding process, the molten plastic is first injected into the mold cavity. After the filling is completed, the melt is cooled and... Read more

23-05-2023 Industry News -

Quickly understand the infusion three way valve

Medical infusion three-way valve is composed of three-way tube, one-way valve and elastic plug. One-way valve is connected to the upper and side ends of the three-way tube, and one-way valve is made at the upper end of the three-way tube On the side ends of the valve lower cover and the three-way pi... Read more

23-05-2023 Industry News